+86-15062519149 | +86-512-58916707

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Energy Saving

High degree of automation , easy maintenance

High Speed Stability , precise and efficient

Human-machine interface control system, high automation,easy operation and safe

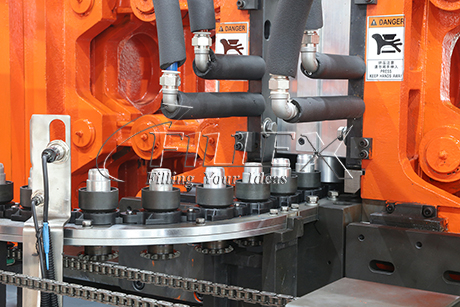

Servo high-speed bottle blowing machine has a stable infrared heating system, the infrared lamp can realize stepless pressure regulation, the bottle embryo pitch is small, the heating efficiency is high, and the heating energy consumption is reduced by 30-40%. The mould of bottle blowing machine adopts drawer structure and is equipped with auxiliary device for assembling and disassembling mould, which is safe and time-saving. Man machine interface control, simple operation, high degree of automation. The automatic bottle blowing machine is suitable for water bottle, oil bottle, medicine, juice bottle, seasoning bottle, carbonated beverage, cosmetic bottle and other packaging containers.

PERFORMANCE & CHARACTERISTICS1.Adopt the linkage structure of servo motor drive Open & close mold and bottom mold.

2.No need equip LP Air compressor,save 30kw/hour of power consumption.

3.Mold positioning installation, easy & quick mold replacement in half an hour.

4.High-speed stabilitv. easy maintenance, single cavity capacity up to 1500bph.

5.Application Scope water.carbonated drink, juice,milk,oil,daily chemical bottles etc.

Energy Saving

High degree of automation , easy maintenance

High Speed Stability , precise and efficient

Human-machine interface control system, high automation,easy operation and safe

Servo high-speed bottle blowing machine has a stable infrared heating system, the infrared lamp can realize stepless pressure regulation, the bottle embryo pitch is small, the heating efficiency is high, and the heating energy consumption is reduced by 30-40%. The mould of bottle blowing machine adopts drawer structure and is equipped with auxiliary device for assembling and disassembling mould, which is safe and time-saving. Man machine interface control, simple operation, high degree of automation. The automatic bottle blowing machine is suitable for water bottle, oil bottle, medicine, juice bottle, seasoning bottle, carbonated beverage, cosmetic bottle and other packaging containers.

Description:

Widely used in daily chemical , lubricant, food , chemical , beverage and other industries . Automatically complete raw material plasticization , extrusion , blow molding , tail removal , bottle mouth cutting and product conveying , which is the advanced equipment for the production of high value-added containers.

PREFORMANCE & CHARACTERISTICS

1. PLC plus human machine interface, touch operation. The fault alarm is self- diagnosis and can be seen at a glance.

2. The center feeding die completely eliminates the product joining line and the color change is quick.

3. The mold is moved by a double linear guide and the center is clamped. Uniform force to ensure that the product cuts are flat

4. The hydraulic system uses proportional hydraulic control and is equipped with imported hydraulic components for precise, stable and energy-saving operation.

5. High speed, high-efficiency, low -energy plasticizing system with excellent mixing and ensuring product purity.

Our bottle blow moulding machine platform provides great production flexibility in term of different types of containers to be produced with the aid of special kits. Bottles for mineral water, soft drinks, fruit juices and functional drinks, beer, edible oil, spirits, dressings, souaces, cosmetics and detergents and pharmaceuticals.

Today, The 6 cavity servo bottle blow molding machine from our factory is delivered to Surabaya, Indonesia.Servo high-speed bottle blowing machine has a stable infrared heating system, the infrared lamp can realize stepless pressure regulation, the bottle embryo pitch is small, the heating efficienc

A bottle blow moulding machine is a kind of machine that is widely used in the canning line of beverage. It could be used to shape hollow plastic parts and connect them. It is also used to form glass bottles or hollow shapes of other materials. Generally, there are three main types of blow molding that are used in the canning line: extrusion blow molding, injection blow molding, and injection stretch blow molding. So, what exactly are the working steps of a bottle blow moulding machine, and what are the precautions for operating a bottle blow moulding machine? Let me introduce them to you in the following contents.

The water-filling production line is used to produce bottled water such as pure water, mineral water, mountain spring water, mineral water, etc., The fully automatic bottled water production line includes water treatment equipment, blow molding machine, bottle feeding air-rail, bottle unscrambler, b

30-45 days after the T/T deposit or L/C.

Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

We will deliver the machines on time as the date we agreed both side.

We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.